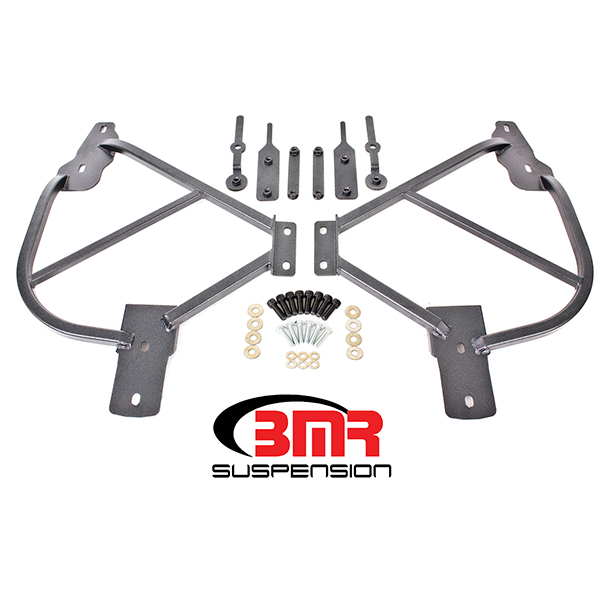

BMR Bolt-On Subframe Connectors

- Dramatically increases chassis stiffness and improves handling

- Manufactured from square steel tubing

- Uses 3/16-inch laser-cut, CNC-formed steel plate

- 100% bolt-in design

- Three attachment points for superior chassis stiffening

- Fully MIG-welded

- Includes all needed brackets and hardware

- Designed for street performance, drag race, and handling applications

- Proudly designed and made in the U.S.A.

$419.95

our shipping promise

low flat rate shipping on orders up to $750. FREE shipping for orders over $750

Reduce chassis flex and increase handling and performance with a three-point bolt-in sub-frame connectors from BMR Suspension. These chassis flex dramatically, even with mild amounts of torque and horsepower. BMR’s sub-frame connectors are manufactured from a mix of heavy-duty square steel tubing, with laser-cut CNC-formed 3/16-inch steel plate, and add loads of strength in all the right places. These triangulated sub-frame connectors are engineered to considerably strengthen the chassis. The SFC015s connect the front and rear sub-frames, but also tie into the rear lower control arm mounts, as well as the transmission tunnel brace.

BMR has designed the SFC015 for the street performance, drag race, and handling applications. This four-point design is far superior to other subframe connectors on the market. The SFC015s solidly link the front and rear subframe, where others only connect the front subframe to the lower control arm mount. This does little to keep the rear of the chassis from flexing. Connecting both sub-frames and the lower control arm mount and transmission tunnel brace, these sub-frame connectors are the ultimate in chassis stiffening. BMR’s SFC015 subframe connectors are 100% bolt-in. This means they can be easily installed with simple hand tools, and no welding is required. When performance is a must, rely on BMR Suspension!

BMR Suspension’s SFC015 are available in black hammertone and red powdercoat for long-lasting good looks. Installation time is about 1 hour. Proudly made in the U.S.A.

| Color | Red, Black |

|---|

Only logged in customers who have purchased this product may leave a review.

[yith_similar_products prod_type="viewed" similar_type="both" cat_most_viewed="no" cats_id="" title="Your Recent Views" slider="no" num_post="6" num_columns="6" order="rand" dots="no" autoplay="no" view_all=" "]

Purchase and earn

Purchase and earn

Reviews

There are no reviews yet.