Radium Engineering Fuel Pulse Damper, Direct Mount Kits

$85.45 – $94.95

-

Add to wishlist- Included-Anodized and laser engraved aluminum top, R=range or XR=extra range

-Anodized aluminum body with male threads, 8AN ORB or 3/8″ NPT

-Stainless steel hardware

-Rubber vacuum hose, 4mm ID

-Vacuum hose Y-fitting

Free shipping for orders over $750.00!

Purchase and earn 86-95 LSXOnly Points worth $0.86-$0.95! *Must be logged in.

Purchase and earn 86-95 LSXOnly Points worth $0.86-$0.95! *Must be logged in. Purchase and earn 86-95 LSXOnly Points worth $0.86-$0.95! *Must be logged in.

Purchase and earn 86-95 LSXOnly Points worth $0.86-$0.95! *Must be logged in.The opening and closing of fuel injectors creates pressure pulses in the fuel rail which can lead to unstable fuel pressure. In order to achieve a safe and consistent rail pressure, a fuel pulse damper (FPD) is often necessary. The FPD’s internal diaphragm will absorb oscillating pulses and stabilize fuel pressure. This correction can be measured throughout the RPM range and can often help idle surge, especially with high flow injectors. Furthermore, a fuel pulse damper can help solve erratic lean air/fuel ratio spikes, commonly experienced as “stumbling”, that are difficult to tune out.

For more in-depth information on the function of fuel pulse dampers, read the Radium blog HERE.

What makes Radium FPDs unique?

Along with having the flexibilty of using common fittings, Radium Engineering FPD’s use a vacuum/boost reference port which allows for proper fuel pulse damper performance even at elevated fuel pressures. This becomes essential for boosted systems that use a 1:1 rising rate fuel pressure regulator.

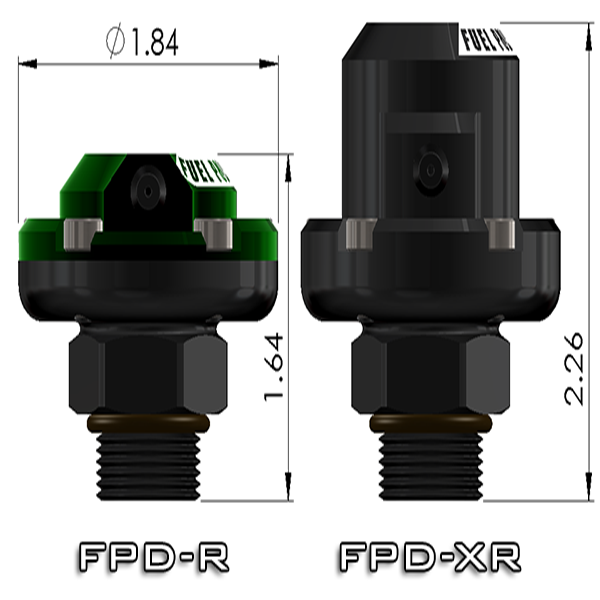

What is the difference between FPD-R and FPD-XR?

The FPD-R (green top) is slightly shorter than the FPD-XR (black top) allowing it to be used in space-contrained applications.

WHICH DAMPER DO I CHOOSE?

The FPD-R (Fuel Pulse Damper-Range) and FPD-XR (Fuel Pulse Damper-Extra Range) both have unique base “static” fuel pressure requirements:

FPD-R base pressure requirement = 40 – 45psi (static)

FPD-XR base pressure requirement = 43 – 78psi (static)

Base pressure is the fuel pressure measured when the fuel pump is running WITHOUT a vacuum line connected to the regulator.

IMPORTANT: The ranges above are base static fuel pressures only. Any dynamic fuel pressure created by a rising-rate FPR outside of this range is acceptable, but only when the base “static” fuel pressure is set within these ranges and the vacuum/boost reference line is connected.

Example 1:

Vehicle: Mitsubishi EVO

OEM Base Static Fuel Pressure: 43.5psi

Boost Pressure: 20psi

Rising Rate Pressure Regulator?: Yes

Notes: Even though fuel pressure is 63.5psi at full boost, either FPD-R or FPD-XR can work in this example because the base static pressure was set within the requirements. Vacuum/boost reference line must be hooked up to the FPD.

Example 2:

Vehicle: 06+ Honda S2000

OEM Base Static Fuel Pressure: 60psi

Rising Rate Pressure Regulator?: No

Notes: The FPD-XR will work in this example because the base static pressure was set within the requirements. The FPD-R cannot be used in this scenario. No vacuum/boost reference hooked to FPD, port left open.

Example 3:

Vehicle: BMW E46 M3

OEM Base Static Fuel Pressure: 72.5psi

Boost Pressure: 20psi

Rising Rate Pressure Regulator?: Yes

Notes: Even though fuel pressure is 92.5psi at full boost, the FPD-XR will work in this example because the base static pressure was set within the requirements. The FPD-R cannot be used in this scenario. Vacuum/boost reference line must be hooked up to the FPD.

Features

The anodized aluminum housing features two selectable threaded male fittings. The 8AN ORB (3/4″-16 UNF threads) version seals using a Viton O-ring while the 3/8″ NPT variation seals with the tapered pipe threads.

The FPDs can be mounted at any possible angle including upside down. For best results, the damper should be mounted directly onto the fuel rail(s).

This product is safe for use with all fuel types including alcohol blends such as E85. Download the installation instructions for more info.

Included

-Anodized and laser engraved aluminum top, R=range or XR=extra range

-Anodized aluminum body with male threads, 8AN ORB or 3/8″ NPT

-Stainless steel hardware

-Rubber vacuum hose, 4mm ID

-Vacuum hose Y-fitting

| Range | FPD-R, FPD-XR |

|---|---|

| Fitting Connection | 8AN, 3/8 NPT |

WHAT CUSTOMERS SAY

Be the first to leave a review.

You are reviewing

Radium Engineering Fuel Pulse Damper, Direct Mount Kits

- Included-Anodized and laser engraved aluminum top, R=range or XR=extra range -Anodized aluminum body with male threads, 8AN ORB or 3/8" NPT -Stainless steel hardware -Rubber vacuum hose, 4mm ID -Vacuum hose Y-fitting

Only logged in customers who have purchased this product may leave a review.

There are no reviews yet.